Now that you’ve tidied up your wardrobe (a la Marie Kondo), it’s time to tackle what to do with all of your unwanted stuff. As we’ve mentioned before, fashion is one of the biggest industrial pollutants in the world, and the last thing we want is to see more clothing end up in landfills. But before you run off to donate your clothes to your local Goodwill, you might reconsider taking them into one your favorite stores. We’ve noticed a number of our retail partners have been getting in on the fashion-recycle game with in-store I:CO donation stations. In fact, you can recycle your used apparel in many traditional brick-and-mortars in exchange for a discount or other incentive. We spoke with I:CO Chief Marketing Officer Jennifer Gilbert about why these collection stations are a game-changer for the sustainable fashion movement.

Now that you’ve tidied up your wardrobe (a la Marie Kondo), it’s time to tackle what to do with all of your unwanted stuff. As we’ve mentioned before, fashion is one of the biggest industrial pollutants in the world, and the last thing we want is to see more clothing end up in landfills. But before you run off to donate your clothes to your local Goodwill, you might reconsider taking them into one your favorite stores. We’ve noticed a number of our retail partners have been getting in on the fashion-recycle game with in-store I:CO donation stations. In fact, you can recycle your used apparel in many traditional brick-and-mortars in exchange for a discount or other incentive. We spoke with I:CO Chief Marketing Officer Jennifer Gilbert about why these collection stations are a game-changer for the sustainable fashion movement.

How did I:CO come to be? “I:CO, which is short for I:Collect, is something that started in Europe in 2009, and then I helped launch the company here in North America in 2010. Our parent company, SOEX, [is] the world’s leader in new and used textile recycle and has been in business now for over 40 years. And because they’ve been in the business this long, they’ve seen firsthand the amount of textiles going to waste. In 2009, they really wanted to start reaching out to apparel and footwear brands and retailers, as well as to the consumer to help change this. That’s really how the I:CO brand and concept was born—from a lot of experience. We were founded on that powerful vision to combat this textile waste issue and ultimately create a sustainable fashion future.

The EPA [Environmental Protection Agency] issues a report every two years, and, just here in the U.S., they say that you and I toss about 81 billion pounds of clothing and shoes every year, and only 16% of that is recycled—going to charity, I:CO partners or your sister or brother in-law. That means 84% is going to our landfills. We want to stop that, so we’ve now become this leading global solutions provider for collecting these items, certified sorting of them for reuse and recycle. We started in Germany and now have offices in the U.S., U.K., France, Japan, and China.

How do you address this issue? “We’re helping brands and retailers embrace this product end-of-use responsibility with a take-back system, meaning they sell all these items to us and we want them to take them back [when we’re done and] give all of our clothing and shoes new life. And we want it to be convenient and rewarding for the consumer. We’ve been out there with our flag since 2009, and it’s been really difficult and exciting.

How do you address this issue? “We’re helping brands and retailers embrace this product end-of-use responsibility with a take-back system, meaning they sell all these items to us and we want them to take them back [when we’re done and] give all of our clothing and shoes new life. And we want it to be convenient and rewarding for the consumer. We’ve been out there with our flag since 2009, and it’s been really difficult and exciting.

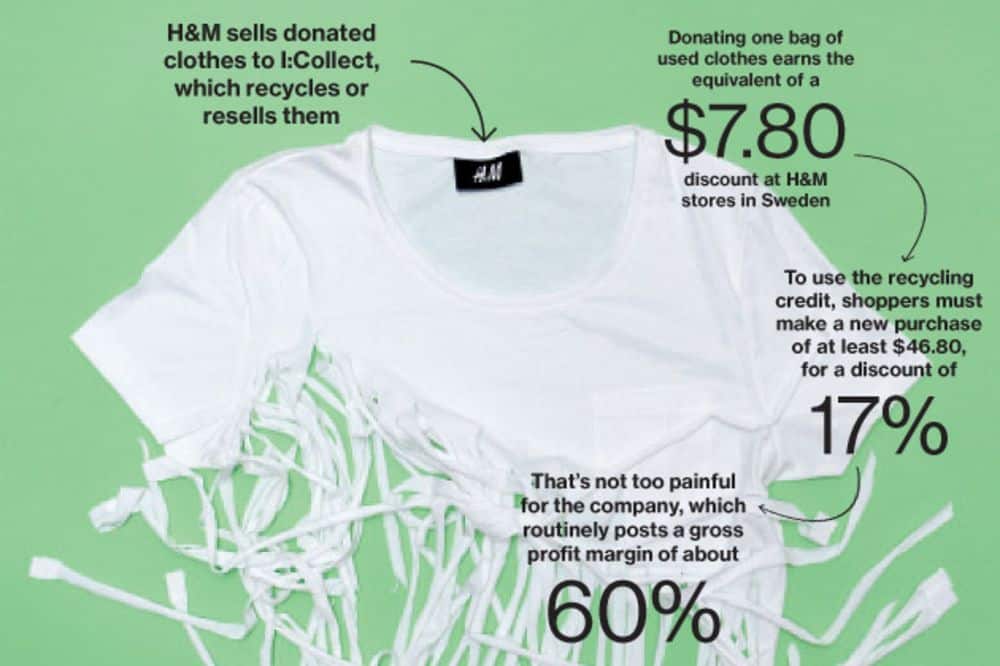

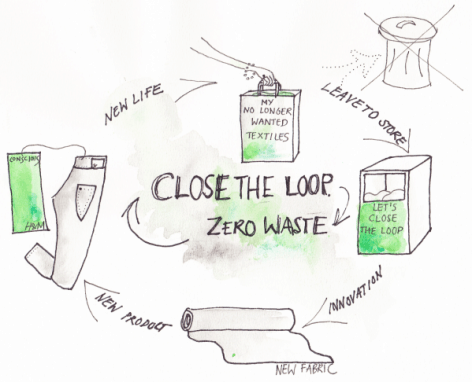

We are for profit, not a nonprofit. With our large partners, we pay them for their collections because we want to make sure they know they’re doing the right thing. Majority of our partners give that back to charity and/or work on innovation projects with us—that’s how H&M worked with us worked on the jeans that have 20% post-consumer content in them. You can read a lot out there about all the different retailers and what they are or aren’t doing, but you’ve got to commend those that are sticking their necks out and talking about their sustainability initiatives. Many don’t want to talk about them because they’re afraid of any backlash. And it’s not just in the fashion industry; it’s all industries. I think we really have to applaud those that are trying to move their industries forward and become circular.”

Were you aware of this issue before starting to work with I:CO? “I was shocked actually. I had no idea the magnitude of this when I started. Growing up, we all brought [our unwanted clothing] to charities. It was an automatic for our family. But for the charities to handle, it’s really difficult. When I started working for I:CO and was really learning about all of this, I went home to Chicago and my dad had pairs of old sneakers and hiking shoes on top of the trash can. I thought he was pulling my leg, and he actually said, ‘Jen, I know that’s what you do. But there aren’t any retailers here yet. I brought it to several charities, and they won’t take them because they’re just too worn. So truly, I have to put them in the trash.’ That spurred me to continue to talk to more brands and consumers—and to continue to learn. So, yeah, when I started I had no idea. I just assumed that everything was being reworn.”

Is it true it’s difficult to recycle certain garments with blended fiber content? “Yes, 100% cotton or 100% wool are more recycle in a mechanical way, and that’s what I:CO helps to achieve. There’s a whole process to that: With jeans, you have to cut out the metal and some of the areas that are harder to chop up, but the pieces are put into a chopper and then it’s turned into a fiber. For the past 20 years, that has been made into insulation products. But we’ve been able to help some of our partners be able to take that, blend it with organic or regular cotton to create the textile to make new denim. This is called a closed-loop or circular economy. When it gets into the poly blends, polyester is an oil derivative. When you start putting that into a mechanical recycle process, it melts and that mucks up the machines and isn’t feasible. There is a lot of innovation, chemical recycle, happening to try to break down those blends—a lot of exciting things on the horizon for that. But it is more difficult.”

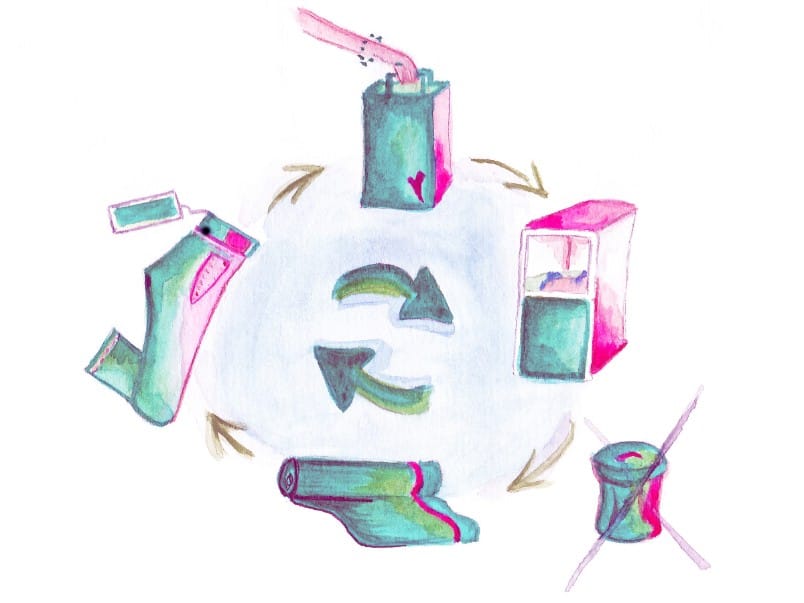

Once you are able to break it down, do you give the fibers back to the same retail partners or different manufacturers? “It’s really important to understand the waste hierarchy when you do these collection programs. We follow Europe’s waste hierarchy: If it’s wearable, it should continue to be rewearable as long as possible. If you look at the resources, labor and energy that went into, let’s say, making that T-shirt, it takes 700 gallons of water to make a cotton T-shirt from growing of the cotton to manufacturing it. So the thought of taking it and shredding it is a little crazy, even if it has a little stain on it. So when we get all of our collections from our partners, we work with our certified, third-party sorting facilities to sort into over 350 categories.

Once you are able to break it down, do you give the fibers back to the same retail partners or different manufacturers? “It’s really important to understand the waste hierarchy when you do these collection programs. We follow Europe’s waste hierarchy: If it’s wearable, it should continue to be rewearable as long as possible. If you look at the resources, labor and energy that went into, let’s say, making that T-shirt, it takes 700 gallons of water to make a cotton T-shirt from growing of the cotton to manufacturing it. So the thought of taking it and shredding it is a little crazy, even if it has a little stain on it. So when we get all of our collections from our partners, we work with our certified, third-party sorting facilities to sort into over 350 categories.

Rewearable is about 60% of what comes through, and that’s resold to second-hand markets around the world. The 40%, then, we’ll look at and say, ‘What’s it’s next best use? Don’t shred that yet.’ If it can be made into squares for wiper cloth, there’s a whole industry for that: the automotive world, the building world. There are bags of used clothing that are cut into rags. There’s designers who want pieces and parts of it, so that’s the next stage in the hierarchy, you can’t rewear it but you can reuse it somehow. And if it can’t be, then you start looking at the fiber content. We only work with partners who are collecting with us to be able to provide fibers and then get into their supply chain to help them. So it takes time to accumulate that volume to provide the fibers.”

You mentioned, in the beginning, you would reach out to brands to get them to participate. With the sustainable fashion movement, do you find that retailers are starting to reach out to you to participate? “It’s been such a journey. It was this mission of getting brand partners on board, and it was—continues to be—educating brands on this textile waste challenge and the importance of creating this circular economy for the industry. So we’re constantly reaching out to them more than them coming to us, but to be honest, the more that [people in the fashion industry] are talking about this, then there’s more awareness. So we are getting brands to call us, but it certainly is still us out there more than the industry coming to us. It’s great when a consumer asks a brand to do this and we’ve had that happen too, which is the ultimate, right? Having a consumer be that careful, caring and conscious.”

You recently added shoes to items I:CO collects. Why was that such a big step? “With footwear, it’s extremely difficult to recycle—there’s a huge range of [types of shoes]. There can be up to 40 different components within [a pair], such as glues. Nike launched a campaign over 20 years ago to take the rubber parts and create running track, the cushy playground material, with that. A lot of shoes come into [our] collections, and 81% is rewearable because there’s such a need for shoes around the world—even if they are kinda beat up. That still left 17% that had to go to landfill, just because there wasn’t much we could do for recycle. So we started working with other partners and academia to research how this could be recycle and what kind of system could be created. After five years, we were able to create this system to take any type of footwear, throw it on the conveyor belt and through this technology of air compression and chopping, it’s able to break down into five different areas of raw materials, from textiles to rubber foam to metal and leather. They come out as different raw materials, and the key thing now is to find markets for that. But we’ve been able to work with some shoe manufacturers to create soles that have a percentage of recycle rubber in it. And metal of course can be resold as a commodity. The tough one is the textiles because they’re very small and have glue on them, so we’re continuing to work towards that. But the exciting thing is we’re working towards zero-waste for shoes, which no one has been able to do.”

What are incentives for consumers to recycle clothes with one of your retail partners? “We make sure every one of our partners give an incentive to consumers. At this point, this is something that is very new and for consumers to really help reduce this textile waste going into landfills and incineration, they need incentive, a call to action. Having an incentive—whether it’s 15% off your purchase, loyalty points, a recycle tote bag, something to get us off our butts to do this—is important. In the future, we hope this is just part of our habit, that we automatically recycle clothes and shoes and never throw them in the trash, and incentives may not be needed. But for now, it’s important part of our program in order to achieve our goals. We need to motivate all of us to do this to make a difference.”

What are incentives for consumers to recycle clothes with one of your retail partners? “We make sure every one of our partners give an incentive to consumers. At this point, this is something that is very new and for consumers to really help reduce this textile waste going into landfills and incineration, they need incentive, a call to action. Having an incentive—whether it’s 15% off your purchase, loyalty points, a recycle tote bag, something to get us off our butts to do this—is important. In the future, we hope this is just part of our habit, that we automatically recycle clothes and shoes and never throw them in the trash, and incentives may not be needed. But for now, it’s important part of our program in order to achieve our goals. We need to motivate all of us to do this to make a difference.”

In light of the retail apocalypse, are incentives working? “The incentives certainly help drive this. I’d like to say it’s all for the environment and the sustainable part of it, but majority is a thank-you-for-getting-me-off-

Who is the most receptive to recycling? “I like going to speak at middle and high school. You can change them easier than older, jaded consumers—already set in our ways. After speaking at my son’s elementary school, I came home one day and he had all of his shoes out on the ground, and I asked him what he was doing. He said, “These are going to my cousin, these I’m keeping and these are going to I:CO—I just got to figure out which store I want to go to.” If we can change that age group around the world and while working with 40 different [global] fashion companies, can you imagine what change we could have?”

What are some of the challenges I:CO faces? “It’s education to the consumer that’s key. The more others and I go out and talk to retailers and brands about what they can do—even with their overages and overstocks, damages and returns, all the way down to their cutting-room floors. Either pre-consumer or post-industrial is easier to manage because you know exactly what’s in that textile because you bought that from the manufacturer. When you get into used goods, you have no idea where that stuff is coming from—where and when it was made, what’s in it, if there’s contamination (like a yogurt spill). I:CO’s taken on that really difficult post-consumer stage.

There’s not a lot of high value in used goods, so every penny counts. Logistics are a big part of this to try and get better at the whole. On the flip side, everything is hand-sorted now. There really isn’t the technology to look at an item and know whether it’s rewearable or recyclable. There is technology being created that’s getting better and better to at least release what its fiber content is, so we can do that efficiently, but there’s so much that needs to be done to make this whole system work. But it’s just going to create more and more green jobs around the world.”

Can we find your collection stations in all your retail partners’ stores? “We usually start with a pilot: 3-month [trial] in a limited amount of stores. It’s more about how the stores handle it, getting input from the consumer, changing marketing materials[, etc.]. Once they’re comfortable and we dial it in, then they roll it out. With H&M, they tested in their Switzerland stores and then they decided—which was unbelievable—to launch all countries at the same time. With Levi’s, we started out in San Francisco, then rolled out to all the U.S., then continued to roll out country by country. Guess started with California, then expanded to all of North America [stores], then to the rest of the world. When they launched last [summer], it wasn’t just to one brand it was all brands (Guess, G by Guess, Marciano, Guess Factory). Every client’s different, but most start out with a pilot to get their feet wet and then take it from there.”

Finally, what are some tips for consumers about how to shop more consciously? “The biggest tip is to not toss anything in your trash. Always try to look at your wardrobe and see how you can repair or reuse it in any way, shape or form. If you can’t find another home for it, go to a participating I:CO partner. Do swaps with friends, find other homes. Never toss it. The other standpoint is look at your clothes: Where are they made? What are they made of? Try to use as many sustainable fibers as you can, and educate yourself on that. What’s great is more and more brands are coming out with their sustainable fiber initiatives. My hope for the future is that everything is made from sustainable fibers, every designer is designing for reuse, so we never have to choose. The ultimate goal is never having to worry about all this, it’s just part of your life. Until then, just be really conscious and learn about everything. Don’t wash your jeans as often—a lot of [environmental] issues, such as water conservation, are happening in our laundry rooms. Learn every aspect about [sustainability], teach your friends and family, and continue the movement.”